Mikros Services / Capabilities

We have top quality equipment and resources to produce the quality products our customers demand.

We have been ISO 9000 certified since 1998 and all production is checked

hourly at all three of our locations, two in Minnesota and one in China.

Services

- Tooling

- Single Source Assembly

- Complete or Partial Assembly

- Procurement of Components

- Packaging and Clean Room Packaging

- Pad Printing

- Silk Screening

- Hot Stamping

- Pre-Production Modeling

- Rapid Prototyping

- Sonic Welding

- EMI-RFI Shielding

- Machining

- Pressure Testing

- Inventory Storage

Our company has over 45 computer-controlled injection molding machines

We specialize in a variety of areas, including tool design using CAD software, injection and insert molding, automation, and secondary operations. Each of these areas are linked together by our Quality Process = Quality Parts philosophy. This creates a framework that allows quality to be proactively inserted into every process resulting in positive outcomes, every time.

Custom Injection Molding

Our current molding machines have the latest updates and computerized enhancements. These help to keep tight tolerances and precise repeatability. We combine this with dedicated robots to ensure that the correct part cycle is maintained throughout the production run.

Tooling

Our engineers have decades of experience in tool design and production. We combine this knowledge with modern tools such as CAD software to ensure that we meet part capabilities and tolerances required by our customers. We have Tooling personnel who are always available to troubleshoot and/or repair any tool as needed. Preventative tool maintenance and tool verification are part of our ongoing quality assurance. This keeps downtime to a minimum and ensures on-time deliveries.

JIT Warehousing

We offer Just-In-Time warehousing capabilities which allows our customers to release products as needed. This gives our customers flexibility and can dramatically reduce their own warehouse requirements, saving them money. We have over 75,000 square feet to accomplish this and have dramatically reduced lead times with this program.

Secondary Operations

● CNC Mill and Lathe

● Manual Machining

● Heat Staking

● Vibration Welding

● Sonic Welding

● Water Testing, Pressure Testing, and More

● Pad Printing and Silk Screening

● Assembly and Medical Assembly

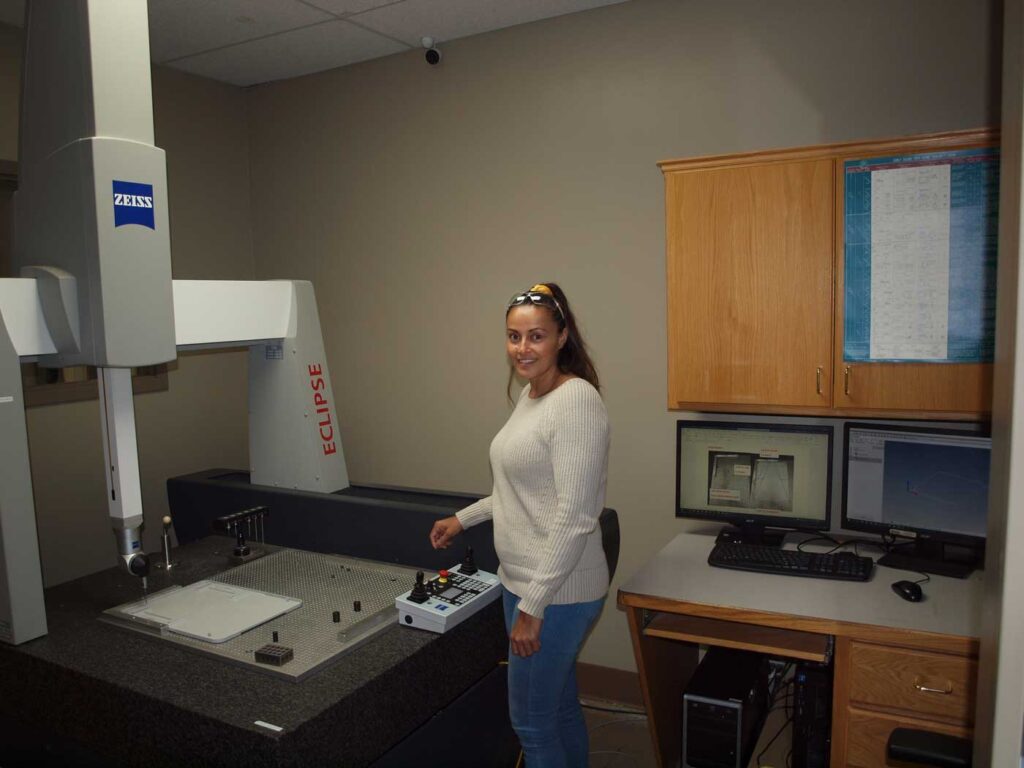

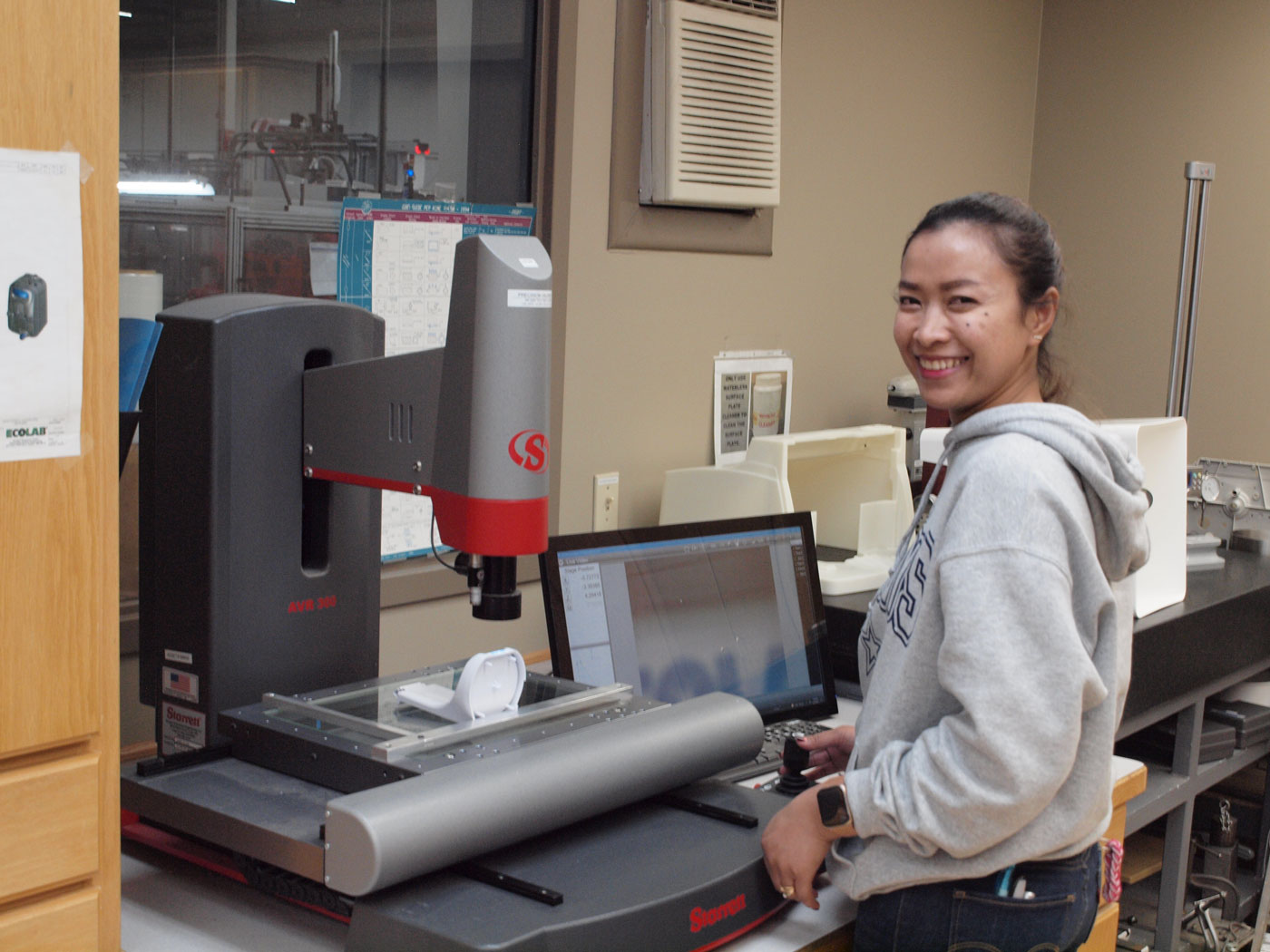

Quality

make sure visual and dimensional requirements are monitored and maintained.